Kaul

Clay Products Company

In

1947 Kaul Clay Products Company from

In January of that year Iroe Dibler was hired as foreman and told to hire a crew to get the plant ready for the manufacture of sewer pipe. Some of the members of the crew were Dominic Alfieri, Harold Hagman, Elmer Kinney, Joe Dibler, Sam Pacanicio, Charlie Cunningham, Fred Hagman, Carmen Grillo, and Frank Hendrickson. Fred Hagman and Frank Hendickson began to do carpenter work and repaired various parts of the plant. The Shamut Railroad brought in several carloads of salt and coal, which we unloaded. The rest of our time was spent in cleaning the factory and repairing some of the kilns. The pay was 88 cents per hour and we worked a 40-hour week.

Since the underground mine had not been used

in years, it was decided to strip mine for clay and also coal. Willard

Rounsville and

After the plant had been repaired the

production of sewer pipes began. Some men from the Kaul Clay Products plant from

Willard

Roundsville, Jr. and Charlie Cunningham began learning to run the press.

Dominic Alfieri began as the clay temperer with Howard Kinney as the

press feeder. The members of the press crew were Harold Hagman, Elmer Kinney and

a man called “Stumpy” from The Kaul plant in

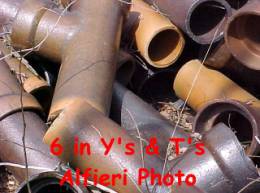

Production began with 4 and 6-inch sewer pipes. Basil Petty arrived from Toronto to do the molding of traps, T’s, Y’s and other molded fittings. He began training Joe Alfieri as a molder. Here are some examples of these fittings.

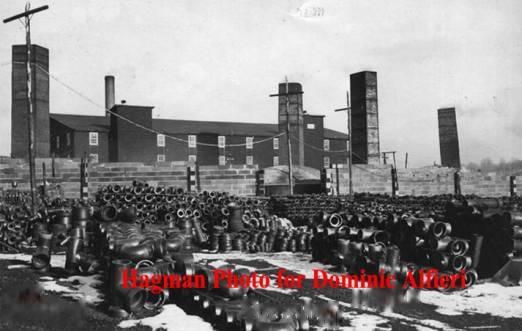

The next Photo shows the various sized sewer pipes in piles in the tile Yard.

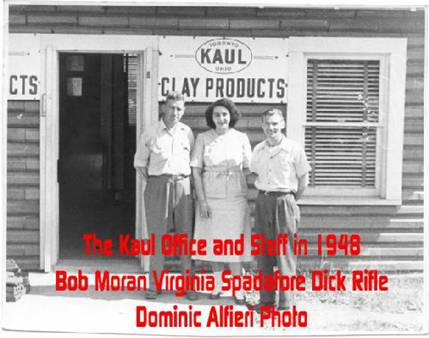

Shortly after Kaul Clay Products Company acquired the Clermont plant Bob Moran was hired as the plant manager by Jim Dyer. Virginia (Dede) Spadafore and Dick Rifle were hired to work in the new office building. The new office building and these three people are shown here.

Production

of sewer pipes moved very slowly since most of the employees were new. Several

people from

With

the addition of these new employees and the extra experienced personnel form

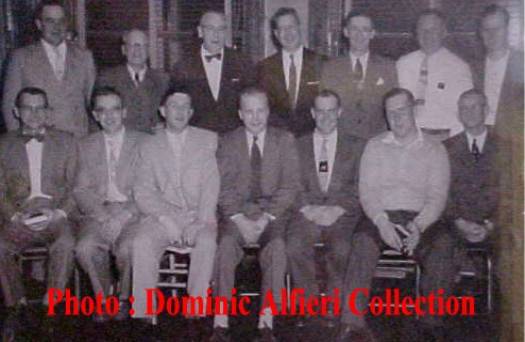

Front

row from left: Dick Rifle, Jack Bish, Curt Peterson, Earl Hite, Bob Dibler, Stan

Arthurs, and Basil Petty.

Second

Row from left: Ray Nieshe, Iroe Dibler, Jim Dyer (Owner of Kaul Clay Products

Company), Bob Moran(Superintendent of Clermont plant), Roger Manning(Shop

Foreman),Gerald Kinney, and Walt Nelson.

Kaul

Clay Products were well known in

A view of the kilns and the yard from inside the factory is shown here.

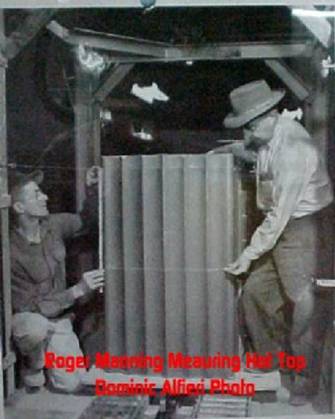

In early 1948 the top lid of the press on the first floor began to leak steam. An effort was made to try to contain it but finally one day the whole lid blew off. Fortunately no one was hurt especially Howard Kinney who sat next to the press on the second floor. His job was to feed the clay to the press. After a short time the press was repaired and production resumed. Shortly after this it became apparent that with the introduction of plastic pipe there was little demand for the sewer pipes. It was decided to begin production of mold used in the steel industry to produce steel ingots. These were called hot tops and a view of one Hot Top being measured as it leaves the press is shown here:

The following photos show some of the various hot tops that were produced for the steel industry:

In

addition to size and shape Hot Tops were different from sewer pipes in another

way. Although they were baked in the kilns, there was no salt or other type of

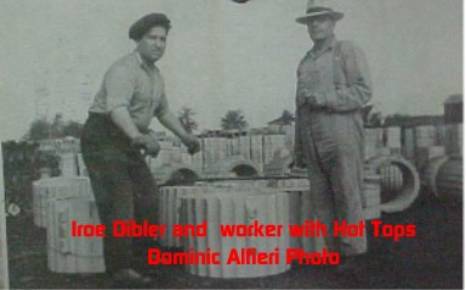

glaze applied. The yard foreman was Iroe Dibler. The following photos show the

yard with the Hot Tops and some of the yard workers.

Since both railroads had closed their service to the Clermont area, it became necessary to ship their products by truck. Frank Paar Trucking from Mt Jewett became the hauling contractor to be employed by Kaul Clay for their Clermont operations.

In early 1948 the wages were 88 cents per hour for the men. In an effort to save the company money Bob Moran began a program of on the job training that enabled the veterans of World War II to sign up and use their G.I. benefits to supposedly learn a trade. Actually it was a way for the company to get cheap labor. The men who signed up for this job training were paid 1 dollar per hour rather than the 88 cents paid to others. The government then reimbursed the company through the G. I. Bill a certain percentage of the wages. Since not all of the veterans were willing to sign up for this training and thus use up their G.I. benefits, the company threatened to fire these men. These men then invited a union representative to try to form a union. Daniel Sandy, a union organizer from the C. I. O., came and helped the men start a union. With the union in place the company was no longer able to threaten the men. In 1955 union called a strike for higher wages. The production of Hot Tops continued as the company switched entirely to their production. By the late 1950’s the demand began to slow as the steel companies began to use other methods of ingot production. In 1960 and early 1961 the sales had dropped by $ 150,000.

This

headline appeared in an article in the

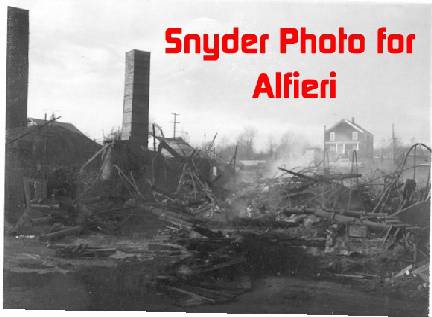

For

the next few days employees cleaned the rubble but by the end of the year only a

skeleton crew remained. Some materials were brought in to fill some outstanding

orders. That proved to be the end of major Kaul operations in Clermont. For many

years there were rumors of possible arson circulated throughout the community

but nothing was ever proven to indicate this idea.

Finally

in 1988 Kaul Clay Products Company filed for dissolution papers and the end of

an era in Clermont.

![]()