Clermont Clay Products

Company

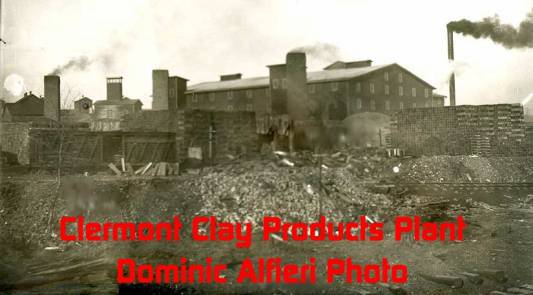

The largest industry in the history of

Clermont was the Tile Plant (as it was known by most residents). The

Commonwealth of

The

local residents also found various uses for some of the sewer pipe as seen in

this 30-inch pipe being used as a planter.

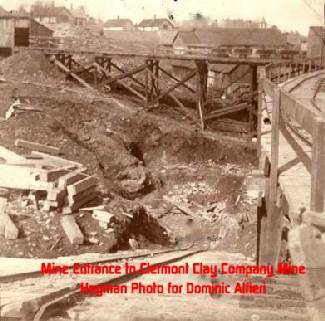

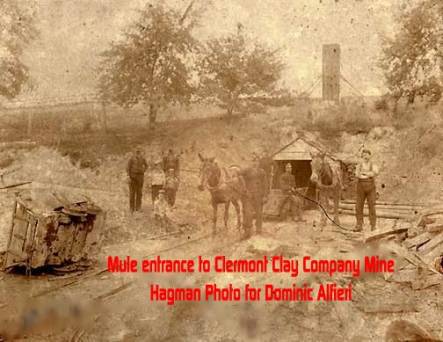

The manufacturing of the tile involved four operations. First was the mine, which supplied the clay for the tile and the soft coal, which was used to fire the boilers and also the kilns.

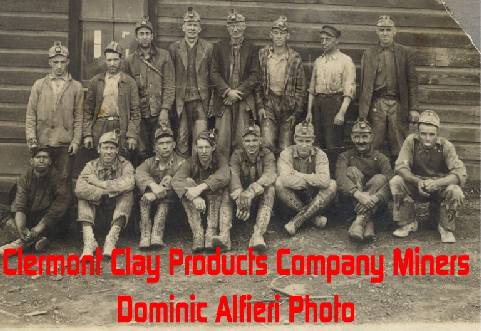

Some additional coal was brought in by rail to meet the needs of the plant. Esther Aloi’s uncle, Harry Flickinger, was the mine foreman. The following miners worked there: Albert Anderson, Willard Rounsville, Fred Hagman, Fred Henry, Art Jacobson, Art Marshall, Kurt Marshall, Leander(Slim) Marshall, Blacky Henry, Dick Johnson, Dominic Cecchi. Aaron Miller, Jim Fowler and Fred Murray. Here is a photo of some of the miners that worked in the Clermont Clay Products Company mine in Clermont.

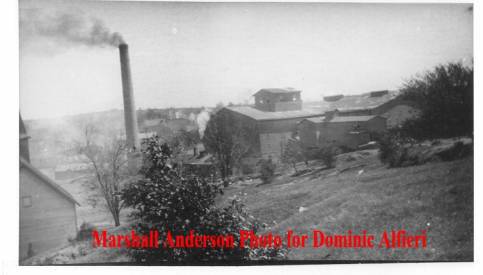

Second, was the factory

complex which included the building where the tile were made, a boiler room for

producing steam, and a blacksmith’s shop for necessary repairs etc.

Third was the kiln area where originally 12 kilns were built.

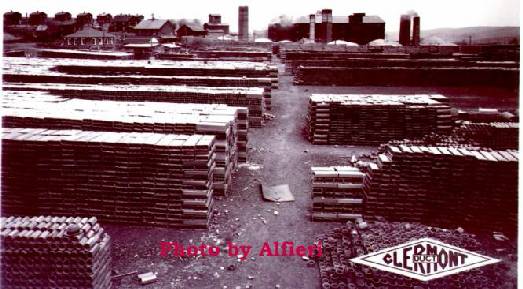

Finally the yard where the tiles were stored until they were shipped.

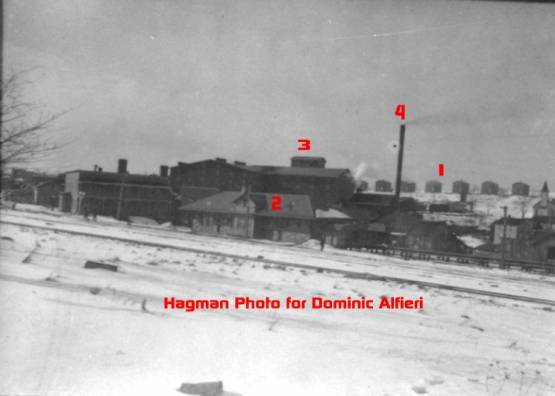

In addition there was a siding from the

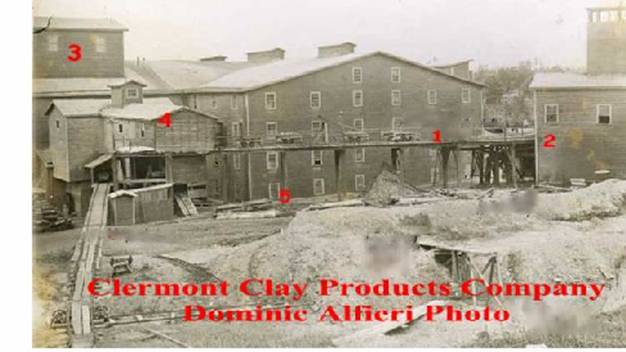

1. Company houses called the Black Row

2.

3. Screening area for screening clay from dry pans

4. Smokestack for the boilers

The factory was a four-story

building with a small room on top that housed the screens for screening the clay

after it had been ground. On the

right side of the first floor in a separate room called the engine room a steam

engine was housed. It served to

drive all the machinery in the plant itself.

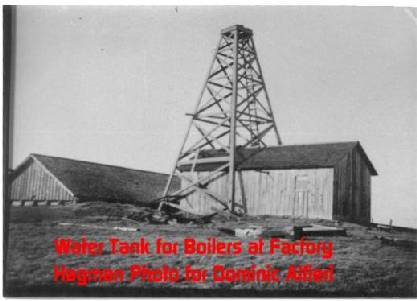

To the right of the factory another building was located that contained

four boilers. They were coal-fired boilers and provided the steam to run the

engine and to provide heat throughout the plant for drying the tile. Water for

the boilers was pumped to a tank on the hill above the boiler room and above the

present day firehouse.

Just below the boiler room was

an entrance to the mine. It was used

primarily to enter and exit the mules that were used in the mine.

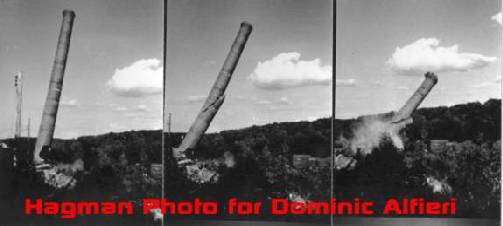

To the right of the boiler room was a huge round smoke stack that served the boiler room.

The

ashes from the boilers were wheeled out and dumped over the bank near the

entrance to the mine. During the 1930’s and 1940’s ashes were used on hills

on the highways and in the local towns. They were used especially the hill from

Hazlehurst to

In the early 1935 the smokestack was struck by lightning and severely damaged. It was decided that it should be brought down and a new one built. It was leaning dangerously so shots were fired at the top of the stack to start its fall. The following photos were taken of this event.

Two bricklayers, Tony

Pascarella and his son Monti, from

1. Track that is used to take raw clay to a bin in a room above the dry pans 2. Shaft house that houses the hoist from the mines (Charlie Nelson was the hoist operator) 3. Room that has the screens in it to screen the clay.4. Room where the clay bin is located directly above the dry pans in which the raw clay is ground. 5. Track that is used to take the coal to the boiler room.

Behind

the boiler room the Blacksmith Shop was located. The blacksmith in the early

days was Bill Reese. His duties included making and repairing various metal

things for the factory. In addition he shoed the mules that worked in the mines.

At first the mules were housed in a barn near the factory but later a barn was built for the mules on the former Frank Smith farm. They were kept in the barn near the factory during the week while they were working and put out to pasture at the other barn on weekends.

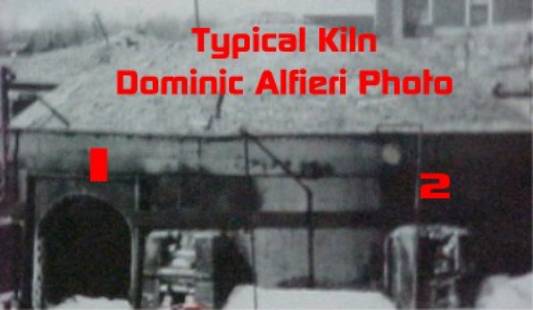

As you face north, to the left of the factory were the kilns and their chimneys. At first there were 12 kilns but in the early 1920’s Tony Pascarella and his son Monti built 4 more for a total of 16. There were 4 square smokestacks with each one serving 4 kilns. There also was a small building that had gauges, which showed the temperature of each kiln. This building also served as place for the kiln firemen to eat their lunches or sit between firings of the kilns. The kilns can be seen in the following photo. This photo was taken at the time when construction of the additional kilns can be seen.

1. View of kilns 2. Black row of company houses

Each

kiln had 8 fireboxes around the outside where the coal was burned to heat the

kiln. It also had a large

round-topped door about 4 feet wide to enable the workmen to load it with the

material to be baked. These features can be seen in the photo shown here.

1.Door to Kiln 2. Firebox

After

the kiln was loaded the door was sealed with brick and soft wet clay with a

small tiny opening to permit viewing of the small heat indicators placed inside.

These indicators allowed the firemen to determine the degree of firing of the

tile.

There were 6 to 8 firemen employed to fire the kilns. The following were

employed in the early years. Frank

Miniaci, John Aloi, Tony Alfieri, Frank Butera, Natale Butera, Frank De Fazio,

and a man known as Felix. An accident happened one time when Felix had a seizure

and fell face down near a firebox and was burned very severally.

He carried horrible scars on his face after that. The foreman also worked

along with the men. He was also overlooked all the shifts. The foreman was Ralph

Aloi.

The four square chimneys that served the kilns can be seen in this picture. It also shows some of the tile yard where the finished tiles were stored until shipped by train to various cities. At this time the factory had three presses for producing both large sewer pipe and different size conduits. There were two vertical presses and one horizontal press, which was called a plug mill. One vertical press was located on the first floor and the other was on the second floor. The clay was brought from the mine in the shaft room and was delivered to a bin on the upper track. There were two dry pans on the first floor at the rear of the factory where the clay was ground into a fine dust. It was hauled up to the screen room on a bucket conveyor belt and screened. From the screens it went down into a bin on the second floor.

The next process was mixing

water with the clay. The wet pans were located in the front right of the

building. A belt drove both the dry and wet pans from a shaft powered by the

engine from the engine room. A man called the clay temperor was responsible for

mixing water with the clay to the right consistency. The clay temperor was Punk

Johnson. After the clay had been mixed to the right degree of wetness and

hardness a bucket conveyer belt carried it to a slide above the press.

A man using a wooden paddle fed the clay into the press every time the

head of the press was raised. The

press crew consisted of the pressman, a former puller, and two men who placed

the green ware on a cart. Each cart was pushed by a man to the elevator in the

center of the plant and taken to one of the upper floors. Another crew of 2 men

would unload the tile on the floor for drying.

The smaller sewer pipes were placed directly on the floor while the large

ones were on a small wooden pallet.

For

all types of fittings there was a section of the second floor set aside as an

area where tees, wyes, ells, collars, reducers, elbows, and traps were molded.

These men had the title of molders.

After the pipe were dry

another crew of men called the setting crew loaded the dry tile on carts and

took them down on elevators located on the rear of the building to the kiln

area.

Gerhart

Anderson was the boss of the setting crew. Some

of the members of the crew were Buster Amend,

One

man in the plant had already cut rings from green pipe and these were used to

set the dry tiles on in the kiln. Usually

one man in the setting crew placed all the dried pipes in the kiln. After the

kiln had been completely full the door was sealed with brick and wet clay except

for a small hole the size of a brick in the door. A set of cones was placed on

the tile to be visible from this hole. Each cone was designed to melt at a

certain temperature and thus enabled the firemen to determine when the salt

glaze was to be applied and when the baking process was over.

After

the tile had finished baking and had been glazed, the brick and clay door was

removed from the kiln. The crew of men known as the “Draw Gang” loaded the

tiles on wheelbarrows and wheeled them on metal tracks to the tile yard. Members

of the gang were Carmen Grillo, Carl Brown, Clarence Silfies, and Clint Silfies.

Iroe Dibler served as inspector and used a small metal tool, which was used to

rattle the inside of each conduit to test for cracks.

They

were stored there until they were loaded in railroad cars to be shipped to

various cities.

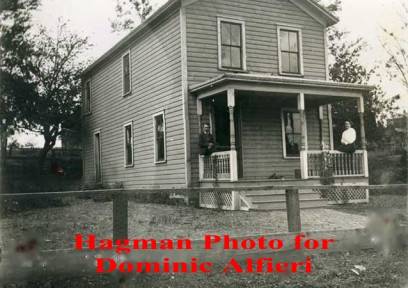

Across from and west of the factory a house was built to serve as

an office.

The

first superintendent was W.E. Ringrose, who with his wife Clara, lived across

the street on the same side as the factory.

Daisy Aloi who lived to the right of the company office spent a lot of

time at the Ringrose household. They became quite fond of her and even sent to a

school. Mr. Ringrose also provided

money for Tony Rizzo, son of Frank Rizzo, to go to college. Mr. Ringrose served

as superintendent until 1920. Jack Allison, a member of the Clermont baseball

team, was the shop foreman at this time. He was offered the job as

superintendent but instead chose to become Mc Kean County detective.

Consequently John Clay became superintendent and served until 1925. At this

point, with plenty of experience in this type of factory, H. K. Leighow took

over the operation. He remained at

the post until the plant closed in 1932.

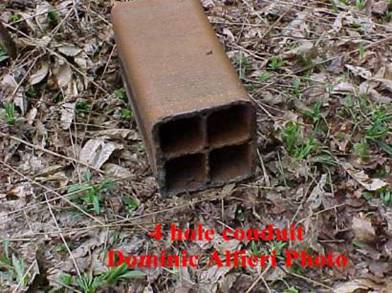

The manufacture of sewer pipe continued until 1919 when the company began to manufacture tile conduits. During this time all the major cities had all their telephone and electrical lines suspended on poles. With the expansion it became a major problem so the solution became fired clay tile conduits. This way the lines could be put underground and the salt glazed conduits would provide excellent cover. The changeover was completed and production began. Western Electric Company became their primary customer. It was necessary to produce various sizes from one-hole conduits to one with nine holes. The larger tile had tiny holes in which iron rods were installed to hold the conduits together. Here are some examples of these conduits:

The small holes for the

iron rods can be seen in the center of the larger conduits.

These

conduits were shipped in boxcars by railroad to cities such as

Clermont

Clay Products Company Houses

As earlier indicated before three rows of houses were built in 1904 when the plant was built. They were called the Black Row, King Row and Queen Row. Some of the tenants in the 1920’s, 1930’s and 1940’s were:

Black Row:

Art Marshall, Leander Marshall, Curt Marshall, Avery Brown, Carl Brown, Mike Valenti and family, Everett Wells Family, Frank Butera, Christmas Butera, Steve Burfield Family, Charlie Peterson Family, Glenn Snyder Family, and Albert Fuller family.

King Row

Charlie Nelson Family, Charlie Billings Family, Earl Eckerd Family, Bill Burford Family, Jim Sample Family, Johnson Family, John Matthews Family, Harry Flickinger Family, Art Marshall Family and Don Simonds Family

Queen Row

Albert Carter Family, Byron Nelson Family, Jack Sample family, Avery Brown Family, Willard Rounsville Family, Fred Murray Family, Tony Spadafore, Fred Russell Family, Ralph Salatino Family, Fred Russell Family, Jim Fowler and wife and Smouse Family

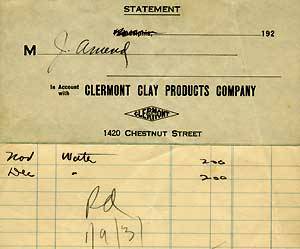

As indicated before Willard Rounsville managed the water works, which was owned by the company but supplied water to other residents besides their company house. The following bill made out to Jake Amend was given in the 1920’s.

By 1930 the need for conduits

had waned in the cities since most of the lines had been laid.

With the slowdown in the economy and the eventual depression the plant

was forced to shut down in the early 1930’s.